Magapal®: Pallet magazine for stacking, storage and distribution

ORGANIZE, OPTIMIZE AND SECURE YOUR PALLET STORAGE AREAS

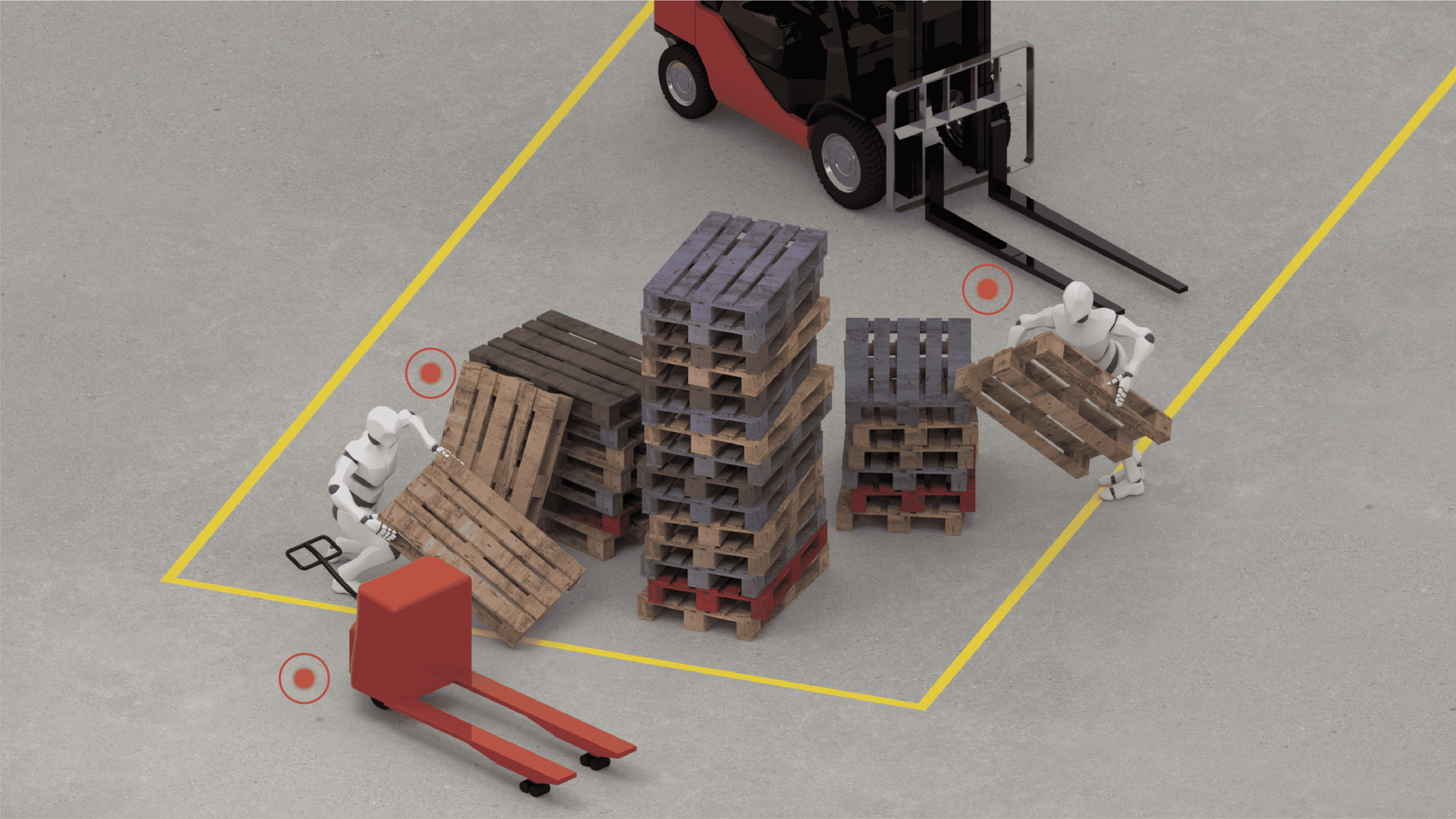

Magapal® pallet magazines are designed and manufactured to meet your specific requirements, ensuring operator safety and improved storage quality for stacked pallets.

Increase productivity and safety with the MAGAPAL® pallet dispenser magazine

Unstack and stack your pallets manually or automatically (via AGV/AMR)

-

How does the MAGAPAL pallet magazine work?

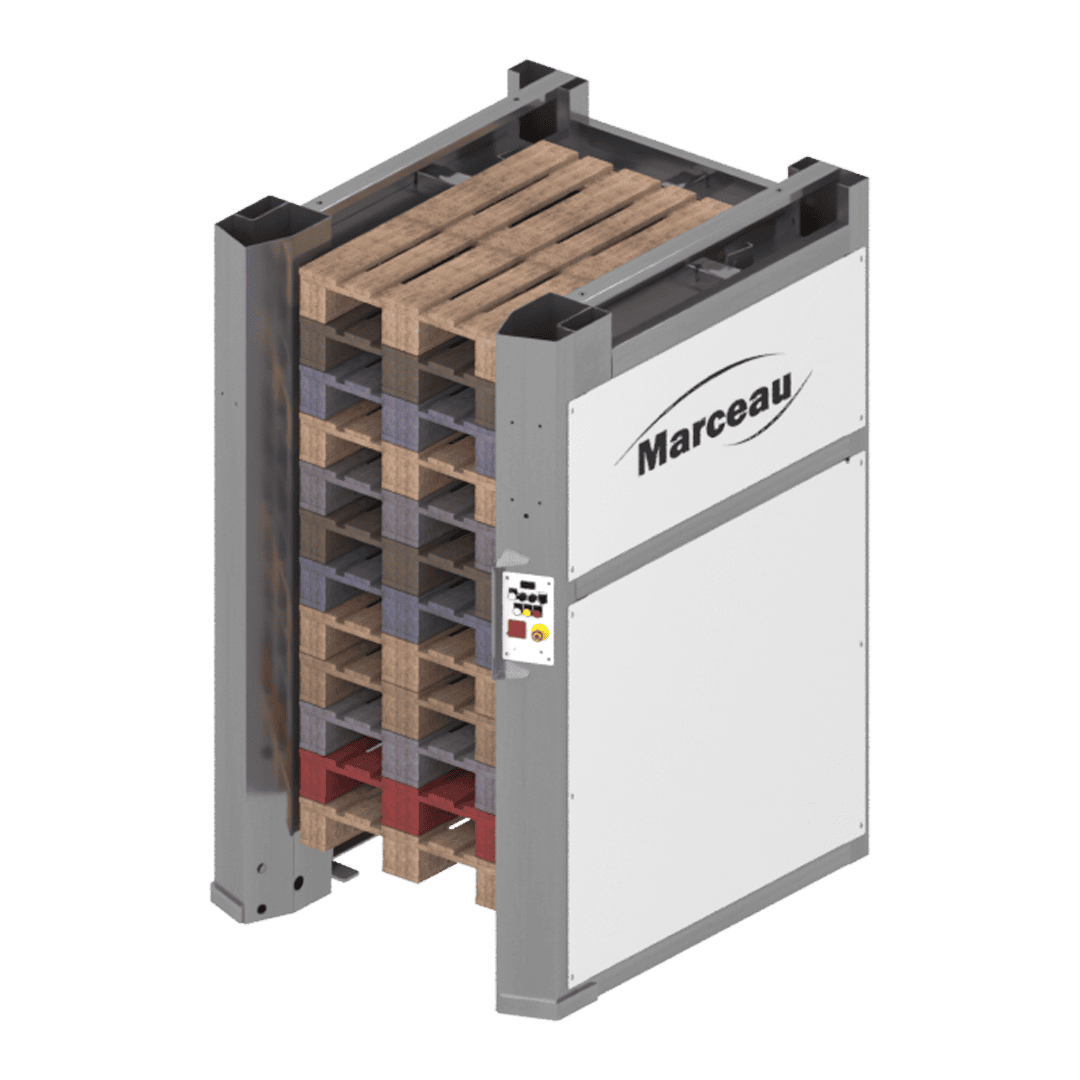

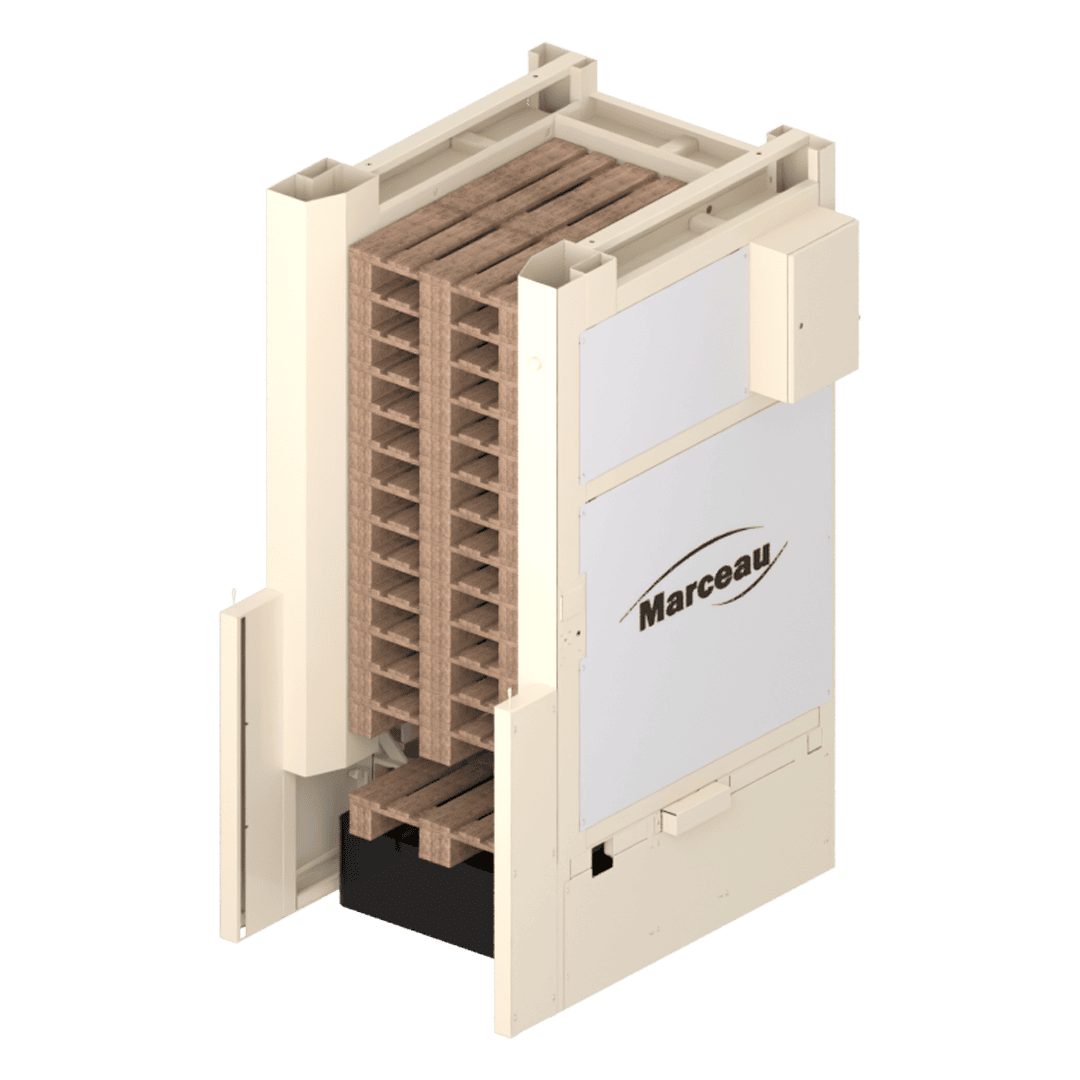

The MAGAPAL offers an autonomous solution for either pallet stacking (Stacker), pallet unstacking (Unstacker), or both, with a simple switch (Mixed).

Thanks to a reliable mechanical process, its mobile arm system performs a lifting and lowering movement; a pallet is then placed on the ground or retrieved and integrated into the stack during a 21-second cycle.

Safety is ensured by sensors located at the base, which immediately stop the movement of the pallet magazine arms in the event of an obstacle.

Autonomous, the MAGAPAL operates in automatic mode. It is quick to install with simple connections and allows for efficient loading or unloading using a forklift.

Ideal for optimizing handling processes, it combines efficiency, safety, and ease of use in a single device. -

What are the technical specifications of the MAGAPAL?

- • Steel chassis painted, hot-dip galvanized, or stainless steel

- • Single or double depth, meaning one or two stacks of pallets

- • Mono-format 1200 x 800, 1200 x 1000, and other formats available

- • Unstacker and/or stacker functionality

- • Stacks of 15 to 30 pallets: wood, plastic, steel

- • Cycle time for retrieving or placing a pallet: 21 seconds

- • Loading with a pallet jack or self-propelled truck

- • Operating environments: standard, cold room, ATEX zone, humid area

-

Quels sont les avantages du distributeur de palettes MAGAPAL ?

- • Prevent users from the risk of falls when manually handling a pallet

- • Avoid back pain and other musculoskeletal disorders (MSDs) for operators

- • Prevent injuries from splinters and nails related to manual pallet handling

- • Limit forklift movement in production and storage areas by allowing each user to supply their station with a pallet jack

- • Feed production lines and workstations at a high pace to improve productivity

- • Improve storage capacity and reduce pallet damage

Applications for numerous industries

Designed and manufactured to suit your environment and requirements

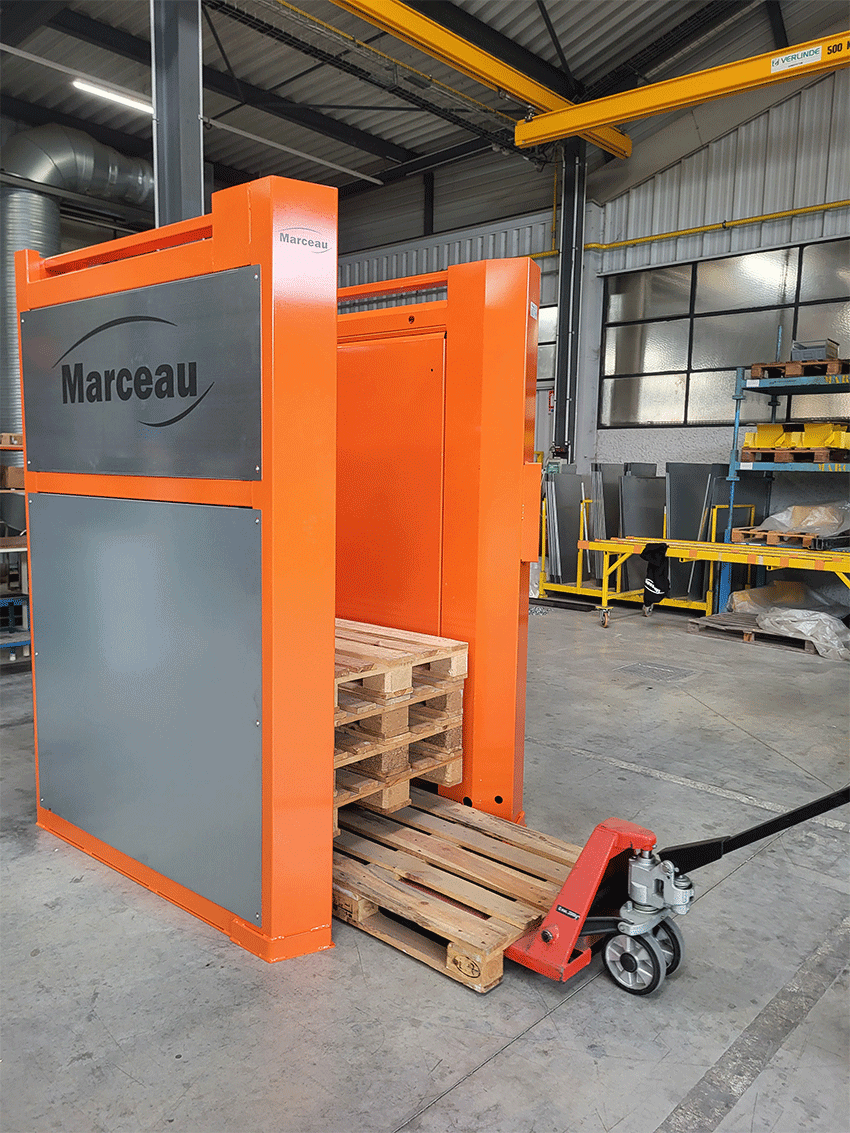

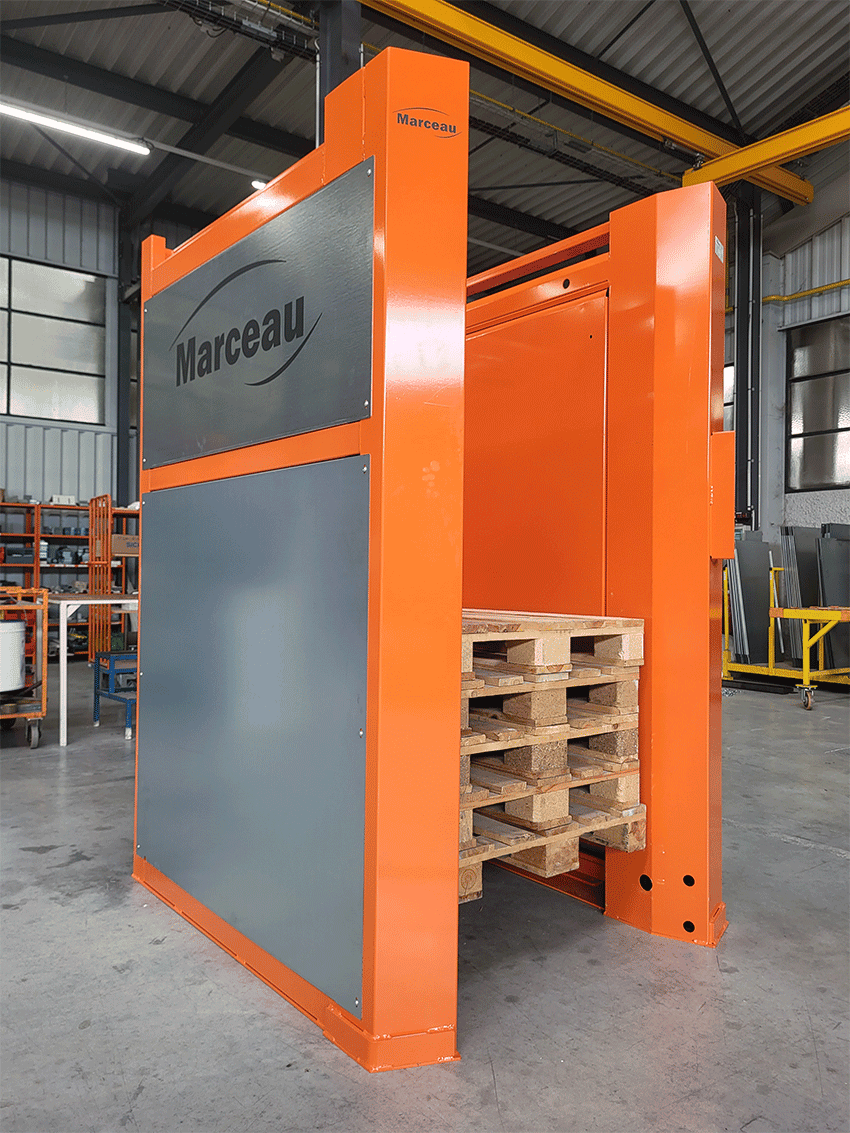

DOUBLE VERSION

Depositing or providing 2 pallets simultaneously. Use of long forked trolleys or pallet jacks.

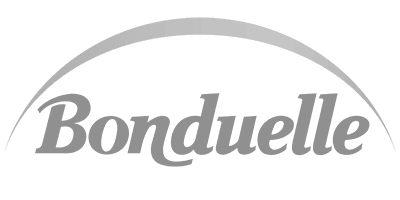

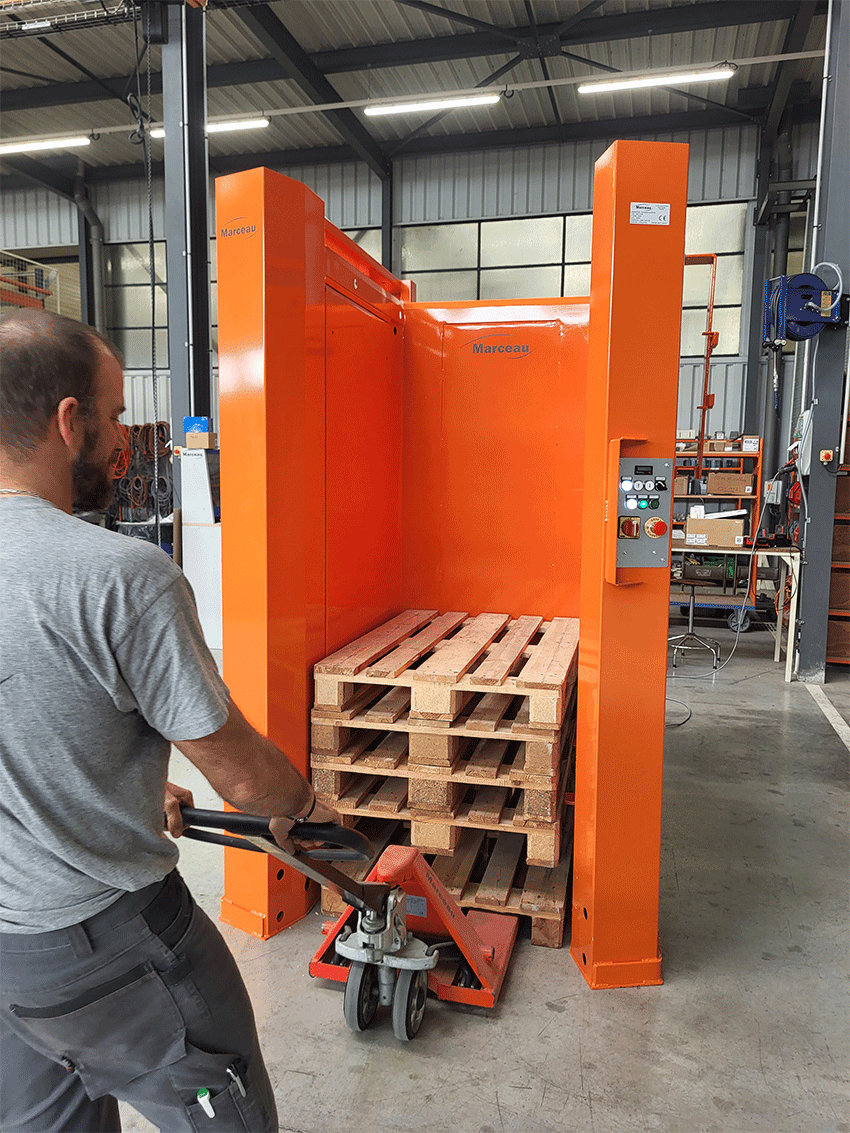

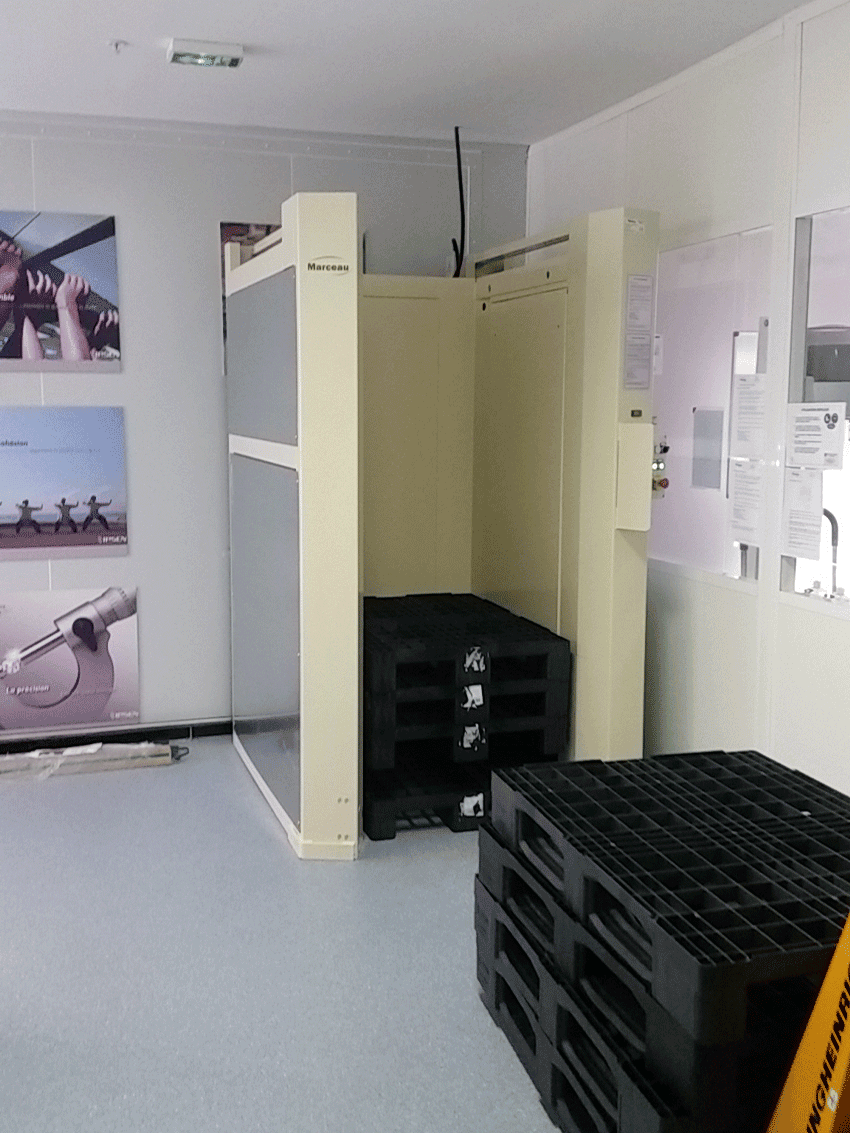

SIMPLE VERSION

Stack of 15 to 30 pallets, operation in standard environment.

STAINLESS STEEL

Operation in specific environments: humid area or ATEX zone.

COLD STORAGE VERSION

Specifically designed to operate in cold rooms down to -25°C.

A guarantee of safety for operators, the Magapal helps reduce accidents and the risk of MSDs related to pallet handling

Request a quote

Our Projects

For over 40 years, the company MARCEAU has specialized in the design of continuous handling systems.

Our customers references